Green Ammonia Production by Haber-Bosch Reactor

27/03/2025

In this article, we will explain how green ammonia is produced using the Haber-Bosch process, covering gas production, reaction conditions, and the role of compression systems in optimizing efficiency.

Gas Production for Green Ammonia

The synthesis of ammonia requires hydrogen (H₂) and nitrogen (N₂) in a specific ratio.

– Hydrogen (H₂): For green ammonia, hydrogen is obtained through renewable sources, for example the water electrolysis, a process where electricity splits water (H₂O) into hydrogen (H₂) and oxygen (O₂). This method ensures high-purity hydrogen production without CO₂ emissions.

– Nitrogen (N₂): Nitrogen is extracted from the air, which is composed of approximately 78% nitrogen. Various methods can be used for nitrogen separation, including cryogenic distillation, pressure swing adsorption (PSA), membrane separation, and chemical absorption.

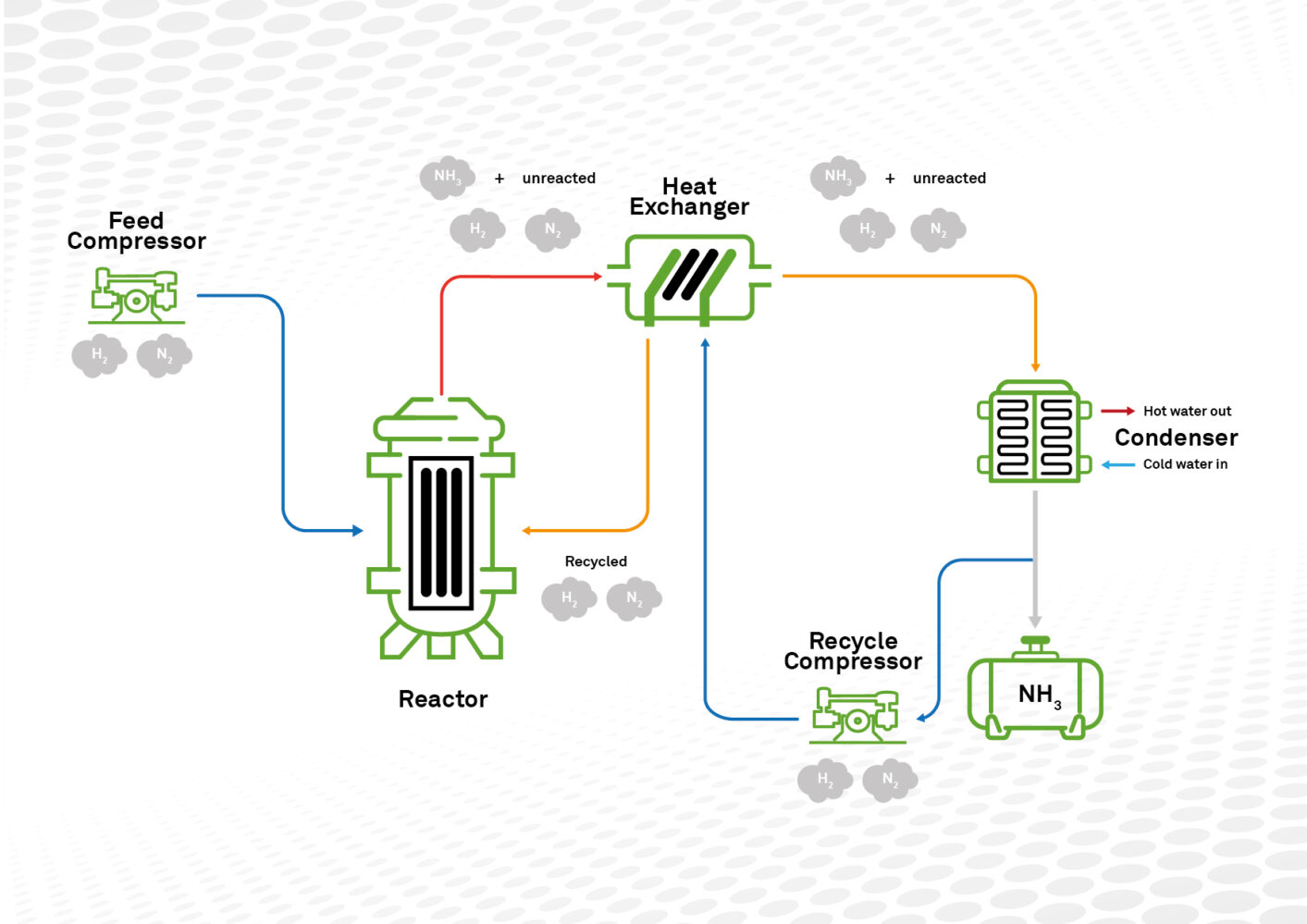

Stages of the Haber-Bosch Process

1. Feed Gas Compression

Once hydrogen and nitrogen are obtained, they are mixed in a 3:1 ratio and compressed to high pressure using a feed gas compressor. In green ammonia processes, the operating pressure is typically around 160 bar.

2. The Reactor

The compressed gas enters a reactor containing an iron-based catalyst, operating at high temperatures (between 400 and 500°C) and high pressures (around 160 bar). Under these conditions, the following reaction occurs:

N2 + 3H2 ⇌ 2NH3

3. Heat Exchange

The reactor output contains ammonia (NH₃) along with unreacted H₂ and N₂. Before continuing the process, this gas mixture passes through a heat exchanger, transferring heat to the incoming feed gases, improving the system’s thermal efficiency.

4. Ammonia Condensation

The gas mixture is cooled in a condenser, where ammonia liquefies and separates, while the unreacted gases remain in the gaseous phase.

5. Recycling of Unreacted Gases

To maximize efficiency, the unconverted H₂ and N₂ are compressed again in a recirculation compressor and fed back into the reactor for further conversion.

6. Liquid Ammonia Storage

Finally, the separated liquid ammonia is stored in tanks for further use in industries such as fertilizers, explosives, and chemical manufacturing.

Compression Units in the Haber-Bosch Process

High pressures are required in the Haber-Bosch process to favor the conversion of hydrogen and nitrogen into ammonia, making compression systems a crucial part of the process.

In the ammonia production process, there are usually two types of compression, a main compression that feeds the reactor and a recirculation compression.

The main compression section can be done in two ways:

Compression Systems Feeding the Reactor:

1. Separate Compression of H₂ and N₂:

-In this approach, hydrogen (H₂) and nitrogen (N₂) are compressed independently to high pressure using dedicated compressors for each gas.

-Once the required pressure is achieved, the compressed gases are mixed in the appropriate stoichiometric ratio (1 part N₂ to 3 parts H₂, as per the reaction) before entering the reactor.

2. Compression of the Mixed Gas (Synthesis Gas)

-Here, the feed gases (H₂ and N₂) are first mixed at low pressure to form synthesis gas (syngas).

-This mixture is then compressed using a single compression system to the required pressure for the reactor.

Syngas Compressor

Recirculation Compressor:

In addition to the main compression system feeding the reactor, the Haber-Bosch process requires a recirculation compressor.

– Function:

-This compressor handles the unreacted gases (N₂ and H₂) that exit the reactor along with the produced ammonia.

-After the ammonia is condensed in the cooling and separation stage, the unreacted gases are compressed and recycled back to the reactor.

– Efficiency:

Recirculating unreacted gases significantly enhances process efficiency by reusing reactants that did not convert to ammonia in the first pass.

Recycle Compressor

If you’d like to learn more about the importance of compression systems in the efficiency of the green ammonia production process, please don’t hesitate to contact us.

Noticias

relacionadas

Feb

Business R&D support programme – ECOPET

Nov

Proyecto Aprovechamiento del calor

Nov

INSTALACIÓN FOTOVOLTAICA (FOTOVOL)

-

CERTIFICACIONES

-

-